- Over 160,000 sq ft fabrication facility on 27 acres

- Lift capacity 80,000 lbs – total crane capacity over 100 tons

- Dedicated Stainless Steel welding shop

- 70+ weld stations, two robotic welders, multiple assembly lines, testing area

- Multiple submerged arc welders

- Cylinder Profiler for vessel production

Capabilites Unmatched

Fabrication

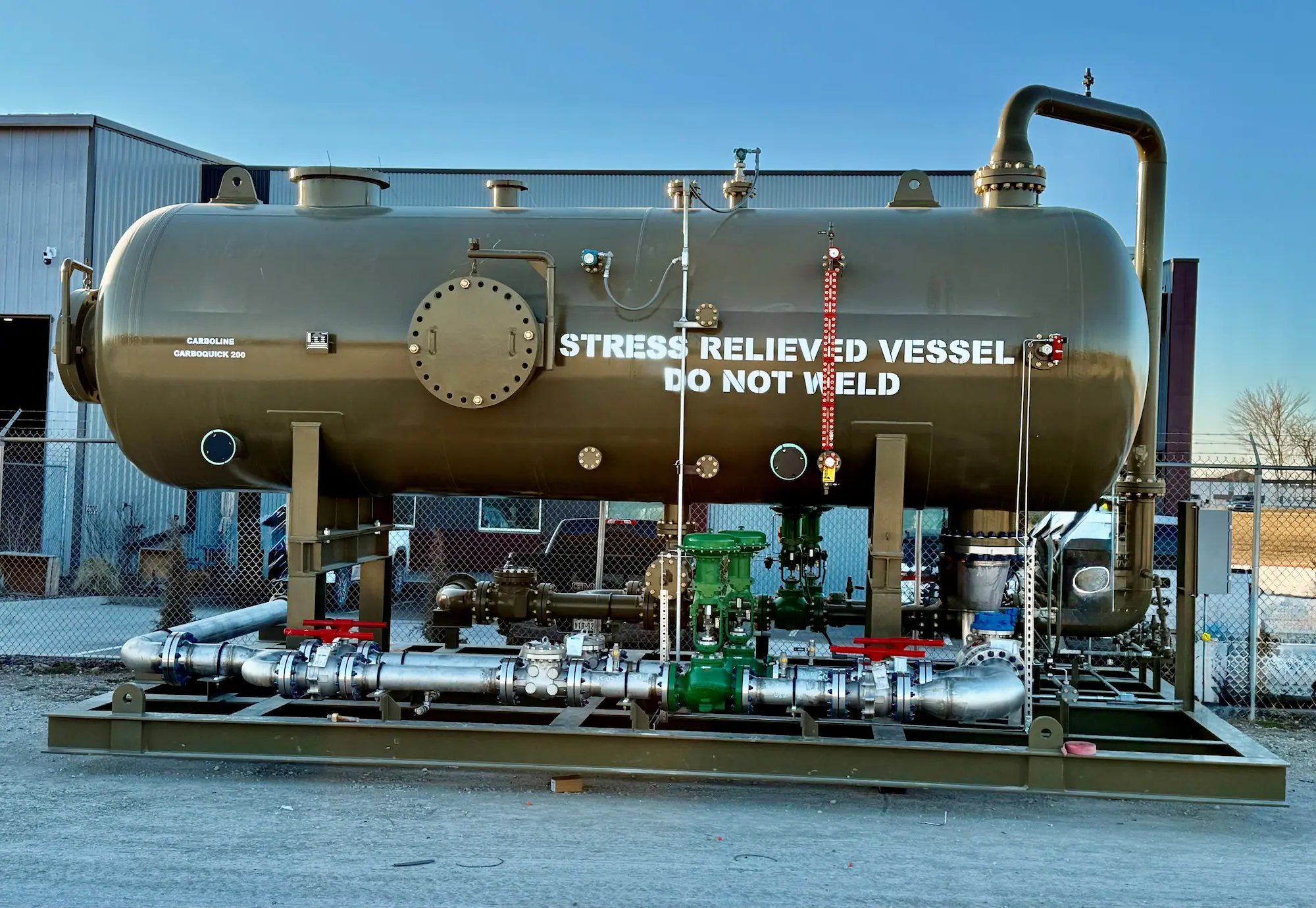

Trident is an ASME Code vessel and B31.3 pipe facility. From purchasing of material to the final assembly, our experienced team holds the utmost quality standards while operating safely in all aspects of the project.

Coating

Trident applies both internal and external coating to surfaces of vessels to meet high level oil and gas industry standards along with FBE pipe coating capability. All work is completed in our climate-controlled facility from blast to final inspection.

Testing

Radiographic testing, hydrostatic, pneumatic, magnetic particle, hardness, charpy impact and welder qualifications.

Accreditations

- ASME Section VIII Division 1

- National Board (NB & R stamp)

- MicroMotion Strategic Partner

Our Culture Begins with Safety

Our mission is to continuously evolve the Trident safety culture in

which our team members live and work. We support safety through multiple levels of personal responsibility that extend beyond the worksite. Whether it’s hiring practices, training, or the safety policies and procedures laid out for our team, we encourage a culture of safe behavior both on and off the job.

Personal Responsibility

Our training and education are specialized to identify potential safety issues applicable to our work environment. Each Trident employee is empowered to ensure the safety of themselves and others before proceeding any task.